Основные рекомендации по обслуживанию общественных игровых площадок

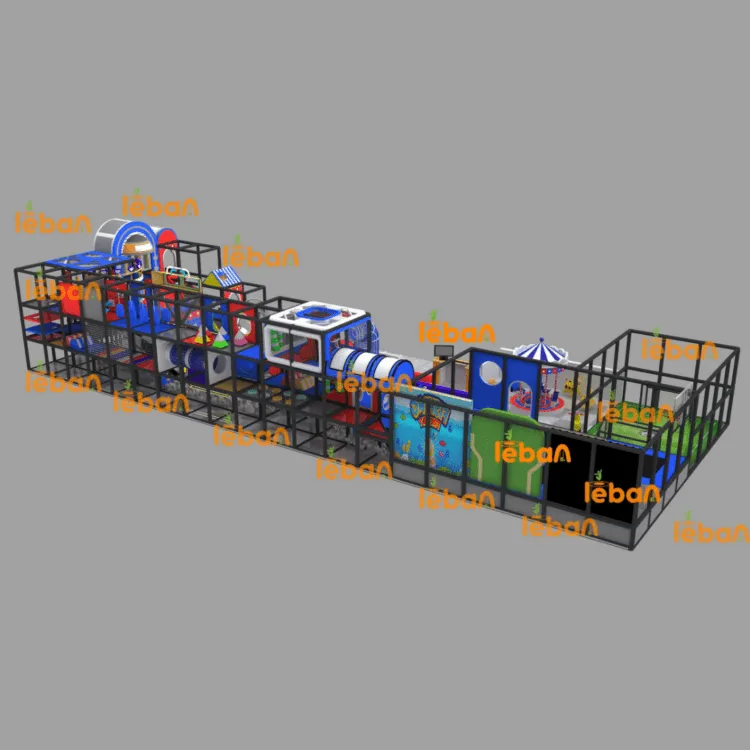

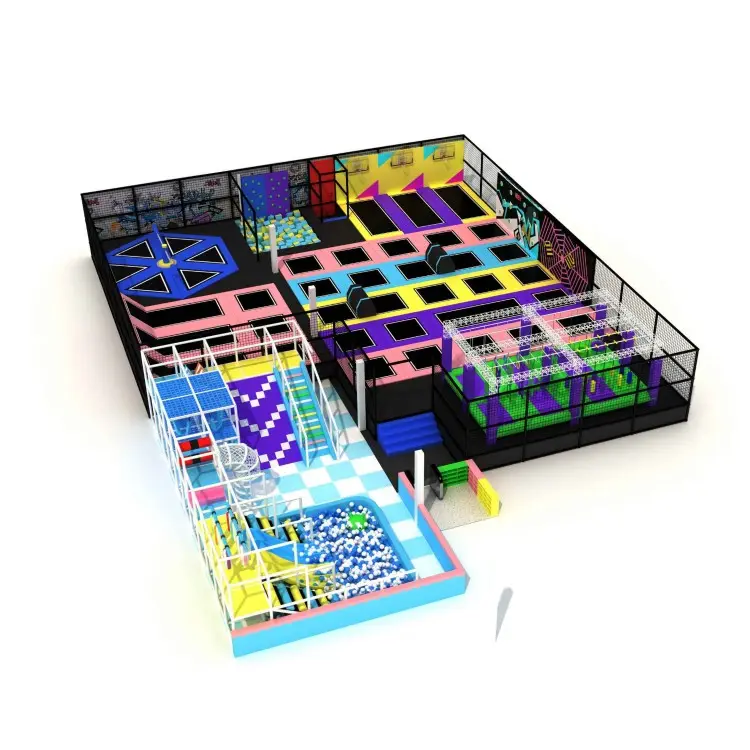

Создание и поддержание безопасных игровых пространств для детей требует преданности делу, профессиональных знаний и постоянного внимания к деталям. Техническое обслуживание детских площадок охватывает все — от ежедневных проверок до долгосрочных стратегий сохранения, которые обеспечивают тем, чтобы эти важные общественные пространства оставались привлекательными и безопасными для маленьких посетителей. Понимание сложностей ухода за детскими площадками помогает сообществам защитить свои инвестиции, одновременно предоставляя детям развивающие преимущества, которые дают хорошо поддерживаемые игровые зоны.

Публичный игровые площадки служат важными местами сбора, где дети развивают физические навыки, социальные способности и создают долгосрочные воспоминания. Однако эти любимые пространства могут быстро прийти в негодность без надлежащего ухода и внимания. Регулярное обслуживание игровых площадок не только продлевает срок службы оборудования, но и предотвращает несчастные случаи, а также обеспечивает соответствие стандартам безопасности.

Ключевые компоненты безопасности детских площадок

Управление материалом покрытия

Основа любой безопасной детской площадки — это используемые материалы для покрытия. Независимо от того, применяется ли измельчённая древесина, резиновая крошка или заливные покрытия, правильное техническое обслуживание имеет решающее значение. Регулярная уборка, выравнивание и проверка глубины насыпных материалов помогают обеспечить достаточную защиту от падений. Зоны под качелями и у выходов с горок обычно требуют дополнительного внимания из-за смещения материала при интенсивном использовании.

Для синтетических покрытий регулярная очистка предотвращает появление плесени и грибка, а также обеспечивает надлежащий дренаж. Необходимо своевременно осматривать швы и устранять разрывы или отверстия, чтобы предотвратить дальнейшее разрушение. Поддержание необходимой толщины покрытия в соответствии с высотой оборудования имеет важнейшее значение для эффективного поглощения ударов.

Протоколы осмотра оборудования

Ежедневные визуальные осмотры позволяют выявить явные опасности, такие как сломанное оборудование или вандализм. Ежемесячные детальные осмотры должны включать проверку всех компонентов оборудования, включая обнаружение ослабленных крепежных элементов, ржавчины, сколов или износа. Особое внимание следует уделять подвижным частям, таким как цепи качелей, подшипниковые механизмы и пружинные качалки.

Фиксация всех осмотров помогает отслеживать закономерности технического обслуживания и демонстрирует добросовестность при содержании игровой площадки. Создание систематического контрольного списка гарантирует, что при регулярных проверках не будут упущены важные элементы безопасности.

Сезонные аспекты технического обслуживания

Подготовка к весне

По окончании зимы игровые площадки требуют тщательной подготовки к увеличению нагрузки. Это включает удаление зимнего мусора, проверку повреждений от пучения грунта вследствие замерзания и комплексную оценку оборудования. Весеннее обслуживание должно включать смазку подвижных частей, затяжку всех крепежных элементов и обновление материалов безопасного покрытия.

Особое внимание следует уделить системам дренажа, чтобы талые зимние воды не вызвали подтопления или эрозии. Это также идеальное время для очистки всех поверхностей оборудования и проверки на наличие повреждений, которые могли возникнуть в холодный сезон.

Стратегии обслуживания в летний период

Пик использования в летние месяцы требует повышенного внимания к содержанию игровых площадок. Ежедневные осмотры становятся особенно важными, поскольку оборудование испытывает максимальные нагрузки из-за постоянного использования. Регулярная уборка помогает предотвратить накопление грязи и бактерий, а частое перемещение покрытия сохраняет необходимую глубину в зонах с высокой ударной нагрузкой.

Высокая температура может по-разному влиять на различные компоненты игровой площадки, поэтому важно проверять резиновые и пластиковые детали на признаки разрушения. Конструкции тенистых навесов следует осмотреть и закрепить, чтобы они продолжали обеспечивать необходимую защиту от ультрафиолетового излучения.

Планирование профилактического обслуживания

Системы документирования

Внедрение комплексной системы документирования позволяет отслеживать мероприятия по техническому обслуживанию и выявлять повторяющиеся проблемы. Цифровые платформы могут упростить этот процесс, обеспечивая быстрый доступ к истории обслуживания, отчетам о проверках и графикам ремонтных работ. Фотографии состояния оборудования могут служить ценным ориентиром для контроля износа.

Ведение подробных записей также помогает обосновать распределение бюджета и продемонстрировать приверженность стандартам безопасности. Эти записи оказываются бесценными во время проверок безопасности или в случае расследования инцидента.

Требования к обучению персонала

Надлежащее обучение гарантирует, что персонал по техническому обслуживанию может выявлять потенциальные опасности и понимать соответствующие процедуры ремонта. Регулярное обновление знаний по стандартам безопасности и методам технического обслуживания позволяет сотрудникам быть в курсе передовых отраслевых практик. Программы сертификации обеспечивают ценные квалификационные данные и стандартизированные базы знаний.

Перекрестное обучение нескольких сотрудников создает избыточность в возможностях технического обслуживания, обеспечивая постоянный уход даже при смене персонала. Регулярные совещания по вопросам безопасности позволяют решать возникающие проблемы и укреплять правильные процедуры технического обслуживания.

Вовлечение сообщества в обслуживание детских площадок

Системы сообщения о проблемах

Создание простых в использовании систем сообщения позволяет членам сообщества информировать обслуживающий персонал о потенциальных проблемах. Быстрое реагирование на такие сообщения демонстрирует приверженность безопасности и укрепляет доверие со стороны сообщества. Мобильные приложения или онлайн-формы могут упростить этот процесс, делая его удобным для родителей и опекунов, чтобы они могли способствовать безопасности на детских площадках.

Регулярное информирование сообщества о мероприятиях по техническому обслуживанию способствует пониманию и поддержке усилий по поддержанию детских площадок. Такая прозрачность может привести к увеличению числа добровольцев и повышению заинтересованности сообщества в сохранении детских площадок.

Программы волонтеров

Организованные программы волонтерства могут дополнять регулярные мероприятия по техническому обслуживанию, одновременно способствуя формированию чувства принадлежности сообществу. Обучение волонтеров из числа жителей основам проверочных процедур создает дополнительный уровень контроля безопасности. Дни волонтерской уборки могут помочь решить вопросы эстетического содержания, а также укрепить связи внутри сообщества.

Установление четких руководящих принципов для волонтерской деятельности обеспечивает то, что такие инициативы дополняют, а не усложняют профессиональные процедуры технического обслуживания. Программы поощрения волонтеров способствуют длительному поддержанию активного участия сообщества.

Часто задаваемые вопросы

Как часто следует проводить профессиональный осмотр игрового оборудования?

Профессиональные осмотры должны проводиться не реже одного раза в год, а на детских площадках с интенсивным использованием — еще чаще. Эти комплексные проверки должны выполняться сертифицированными инспекторами по безопасности игровых площадок, которые могут выявлять потенциальные опасности и рекомендовать необходимый ремонт или замену.

Какие наиболее распространенные проблемы с обслуживанием детских площадок требуют немедленного внимания?

Немедленное внимание требуется при наличии сломанного оборудования, открытых острых кромок, ослабленных крепежных элементов, поврежденного защитного покрытия и любых конструктивных проблем, которые могут нарушить устойчивость. Эти опасности создают прямой риск для безопасности и должны устраняться сразу после выявления, возможно, с временным закрытием затронутого оборудования.

Как погодные условия могут влиять на потребности в обслуживании детских площадок?

Погода существенно влияет на потребности в обслуживании детских площадок посредством различных факторов: ультрафиолетовое излучение может разрушать пластиковые компоненты, влага способствует образованию ржавчины и гниению, перепады температур вызывают расширение и сжатие материалов, а экстремальные погодные явления могут повредить оборудование или сдвинуть покрытие. Графики технического обслуживания должны учитывать местные климатические условия и сезонные изменения.

Какая документация должна вестись при обслуживании детских площадок?

К числу необходимых документов относятся журналы ежедневных осмотров, подробные записи о техническом обслуживании, история ремонтов, гарантии на оборудование, измерения глубины безопасного покрытия, отчеты о происшествиях и сертификаты профессиональных проверок. Эти документы следует хранить в соответствии с местными требованиями и рекомендациями по управлению рисками, как правило, в течение нескольких лет.

Содержание

- Основные рекомендации по обслуживанию общественных игровых площадок

- Ключевые компоненты безопасности детских площадок

- Сезонные аспекты технического обслуживания

- Планирование профилактического обслуживания

- Вовлечение сообщества в обслуживание детских площадок

-

Часто задаваемые вопросы

- Как часто следует проводить профессиональный осмотр игрового оборудования?

- Какие наиболее распространенные проблемы с обслуживанием детских площадок требуют немедленного внимания?

- Как погодные условия могут влиять на потребности в обслуживании детских площадок?

- Какая документация должна вестись при обслуживании детских площадок?