Leban Amusement Co., Ltd. was founded by Kay, Jone and Stiven. Before the company was founded, they have been working in playgrounds and toys industries for more than 12 years.

To bring the children safe, fun and the most affordable products in the industry, they decided to start a new adventure. So here comes the Leban Play. Happy play & Happy accompany. Where does the name "leban" come from? Leban means "Happy accompany" in Chinese, we wish everyone would find their happy in the play world. Bringing joy to children by creating equipment that fosters social, intellectual, and physical growth is our vision.

Cut out the middleman. By manufacturing everything in our own [20,000] sqm facility, we eliminate extra costs. You get premium quality equipment directly from the source at the most competitive market rates.

Safety is our bottom line. We never compromise on materials or standards. Our products are rigorously tested to meet global safety certifications, including ASTM F1487 (USA), EN 1176 (Europe), AS 4685 (Australia), and CSA Z614 (Canada), ensuring a worry-free environment for kids.

Proven track record. With over 20 years of experience, we have successfully delivered projects to [70+] countries. From the USA to Europe, our global footprint is proof of our reliability and quality.

We make it easy for you. From free custom 3D design to manufacturing, shipping, and installation guidance, we handle the complex details so you can focus on running your business.

Join Leban Amusement Co., Ltd. and be part of our mission to bring joy and growth to children through safe, fun, and affordable play equipment. With over 12 years of industry experience, we offer innovative products and reliable partnerships. Let’s create a happier play world together.

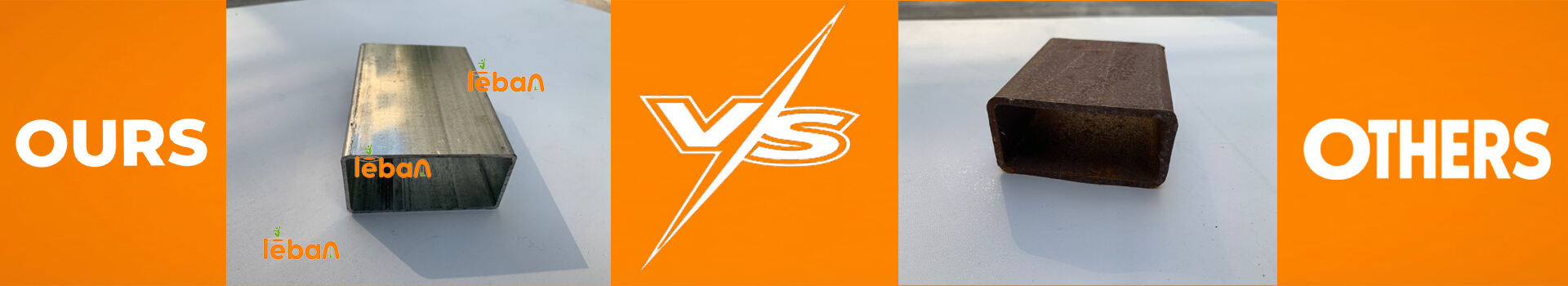

1.Thickness : 2mm - 4mm(solid & durable)

2.Risk : Zero Deformation. Built to withstand 10+ years of heavy use

3.Weight : Heavyweight (Maximum safety for you)

1.Thickness: Thin (< 2.0mm). Fragile & hollow.

2.Risk: High Deformation Risk. As seen in the photo, the walls are prone to denting and bending. Short lifespan (< 3 years).

3.Weight: Lightweight. Unstable structure, posing potential safety hazards.

1.Chaotic Packing ? Pipes are often mixed randomly in containers to save the space, which make the workers to waste several days to organize the pipes before installing

Smart Order Packing : We can pack pipes orderly according to the pipe number, which allow the workers to use it quickly before installing them. Your team can identify parts instantly and start installation immediately.

2.Missing or Hidden marks ? During installation, the bottom part of the pipe is often buried in cement or hidden by fasteners. If the mark is covered, your team has to guess, leading to costly mistakes.

Always-Visible Markings : We mark the pipe number at both ends (0.5m from the top and bottom). No matter how deep the pipe is buried or where it is clamped, one mark will always be visible to your installers.

3.Missing parts found during installation ? Discover a bent pipe or missing component during installation is nightmare for us, which will delay our project schedule for weeks.

Pre-assembly guarantee : We refuse to ship blindly. Before packing, we conduct rigorous pressure testing and pre-assembly to ensure every piece arrives in perfect condition with absolutely no missing parts.

1.Precision-Molded for structural integrity: unlike other companies who rely on generic components,we design Proprietary Molds for all our connectors, it ensure a perfect fit for every joint, eliminating the structural play and wobbling which found in inferior setups

2.Dual-Layer corrosion defense: our clamps are forged from high-tensile galvanized steel and finished with Electrostatic Powder Coating. This dual-layer shield create impenetrable barrier against rust, moisture.

1.Multi-Layer Core: Others always choose to use standard 1.0-1.5cm red plywood,but we choose to use 2.0cm - 3.0mm Environmental multilayer plywood. This doubles resistance and stability

2.Tactile Comfort: we use sandwich structure: 2cm Foam + 1cm Sponge

The extra sponge layer create soft touch and protect children's knees

3.PVC material: we use 1000D Matte 0.55mm PVC. It is the highest industry standard: Fire-proof,resist scratch and prevent from slipping

1.Strong Resilience: unlike normal sponge padding that flattens over time, our noodles use high density EPE core, which has closed-cell structure offers superior memory retention and make the padding rebounds after impact.

2.Armored Protection: wrapped in glossy PVC vinyl, our noodles can against wear and tear. And the coating is UV-stabilized,which can prevent the material from cracking,fading,becoming brittle under the sunlight

3.Resist Fire: our materials meet ASTM fire-resistance standards to provide compliance assurance and peace of mind

1.4mm Wall thickness: unlike other competitors settle for 2.5mm or 3.0mm tubing, but we refuse to compromise on structual integrity. And we use 80mm x 80mm Galvanized Steel Tubes and leading 4mm Wall Thickness. This ensures our frame can withstand decades of impact without deformation

2.Standblasting: every steel frame undergo rigorous sandbalsting to remove surface contaminants and also increase surface roughness for maximum adhesion

3.Dutch AkzoNobel Powder Coating: we use dutch akzonnobel powder coating which allow our steel frames become more durable than standard paint and also resistant to scratching peeling and corrosion

1. Piano wire: The soul of trampoline is springs, unlike other companies use the common 65Mn Managanese steel, we upgrade the material to High-carbon Piano Wire (ASTM A228) , this is the same material used in high-stress automotive components because of its supreme tensile strength and elasticity compared to normal steel

2. 5 times Lifespan compared to ot

3. her material : our piano wire springs are anti-fatigue and it has exceptional shape memory

4. Advanced Protection: our each spring undergo a Deep Galvanization process to create a tough, rust-resistant barrier to against humidity and sweat.

1.0.55mm PVC skin: not like other company choose to use thin, flimsy covers, Lebanplay use extra-thick 0.55mm PVC skin with a verified tensile strength of 130N.M. It can resist tearing, cracking, fading even under the most intense daily traffic

2.100mm high density EPE core: safety is about thickness, unlike other companies choose the cheap sponge foam that flattents out and absorb water causing mildew, LebanPlay choose 100mm layer of Eco friendly EPE foam, which can absorb shock and have permanent shape memory, protect jumpers from hard frame impacts

1.ASTM-compliant PP Material: the jumping mat is the primary component of park, LebanPlay uses ASTM-compliant PP material imported from USA, which is known for its high tensile strength and UV stabilization and also can withstand continuous dynamic loading without losing tension or becoming brittle overtime

2.8 rows of UV-resistant polyester stitching: structural integrity is about the seams. Not like other companies choose the normal seams. LebanPlay choose 8 rows of UV-resistant polyester stitching along the mats' perimeter. The V-rings are attached using a reinforces zitg-zag pattern to distribute stress evenly, minimizing the risk of tearing ast connection points

3.Two Material Options Available:

a.Standard Black PP Mat (commercial standard): manufactured from high-density woven polypropylene. Its tight weave provide slip resistance and structural stability, ensuring safety for general users

b.High performance string mat (professional standard): This mat use a specialized open-weave string structure that allow that allow airflow throguh the mat which delivers a more powerful bounce and higher energy return compared to stadard mats

1.High-strength Aluminum Alloy: we use Aviation-Grade Aluminum Alloy for our truss structures. Unlike traditional steel, it can ensure maximum structural integrity without excessive mass

2.Reduced Static Load and easy installation: primary advantages of aluminum is its weight, almost 1/3 of the steel. This significantly reduces the weight and this lightweight nature allow for faster installation process, and reduces labor cost and setup time

3.Corrosion Resistance: this material is can prolong its longevity, and aluminum truss frame have protective oxide layer that resist corrosion and rust. Unlike other company choose the steel frame that need painting and galvanization to protect them from degradation. And compared to steel truss frame, aluminum remains clean and don't need maintenance for years

1.Certificate TUV Approved: LebanPlay choose clmaps which are TUV certificated for the reason that it can bear full dynamic weight of children and each unit have Load capacity of 500 KGS (approximate 1100lbs). It can provide a massive safety margin to withstand intense swinging and impact wihout slippage and fracture

2.Specialized Clamp Types: LebanPlay use different types of clamp for different structures to make sure the rigidity and ease of maintaince

a.Swivel Clamps: it is designed for connecting the truss structure with horizontal cross bars. And this 360-degree swivel mechanism allow flexible angel adjustment during installation and locks it to create a rigid, non-deformable frame

b.Eye bolt clamps: it is designed for connecting the horizontal cross bars with hanging obstacles. And this heavy-duty eyelet mechanism ensure dynamic swinging while allowing for easy disassembly to replace or upgrade obstacles